PCR machine|Do you really understand?

Nobel Prize-winning PCR technology

In 1993, American scientist Mulis received the Nobel Prize in Chemistry, and his achievement was the invention of PCR technology. The magic of PCR technology is in the following characteristics: Firstly, the amount of DNA to be amplified is extremely small, and theoretically one molecule can be used for amplification; secondly, the amplification efficiency is high, and the amount of the target gene is exponential. Amplification, more than 10 million times in a few hours. Now the PCR instrument has been widely used in life science research and many other aspects.

Different models and manufacturers of thermal cyclers may exhibit different performance and repeatability. These differences affect not only PCR efficiency but also the accuracy and consistency of data obtained. Understanding PCR machine features can help us maximize the success of our experiments.

Heating module

The accuracy of the temperature of the thermal cycler can be decisive for the success or failure of PCR. Well-to-well temperature consistency on the heating block is also critical to obtain reliable and reproducible PCR results.

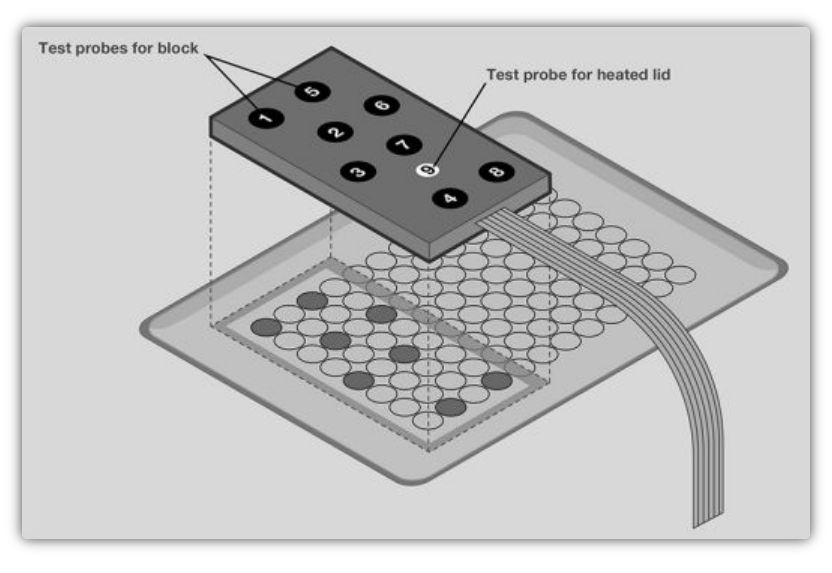

One way to ensure thermal accuracy is to test frequently using temperature verification kits and recalibrate as needed by a trained professional. Temperature verification tests are typically used to:

Well-to-well accuracy relative to set temperature in isothermal mode

Well-to-well accuracy relative to set temperature after temperature conversion

Heat Lid Temperature Accuracy

Primer Annealing Temperature Control

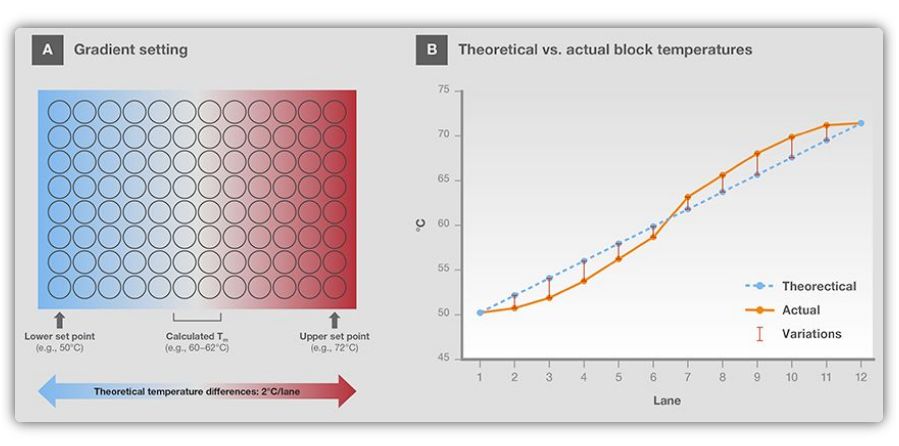

Gradient temperature control is a function of the PCR instrument that facilitates the optimization of primer annealing in PCR. The purpose of the gradient setting is to achieve varying temperatures between modules, and by ≥2°C temperature rise and fall between each column, different temperatures can be tested simultaneously to obtain the optimal primer annealing temperature. Theoretically, a true gradient achieves linear temperature between modules.

However, conventional gradient thermal cyclers typically employ a single thermal block and control temperature through two heating and cooling elements located at both ends, often resulting in the following limitations:

Only two temperatures can be set: the high and low temperatures for primer annealing are set at both ends of the thermal module, and precise setting of other temperatures cannot be achieved between modul

Due to the heat exchange between the different columns, the temperature between different regions on the module is more likely to follow a sigmoidal curve rather than a true linear gradient.

Sample temperature

The ability of the thermal cycler to control the sample temperature is very important for the accuracy of the PCR results. Instrument-specific parameters such as ramp rates, hold times, and algorithms are critical for predicting sample temperature.

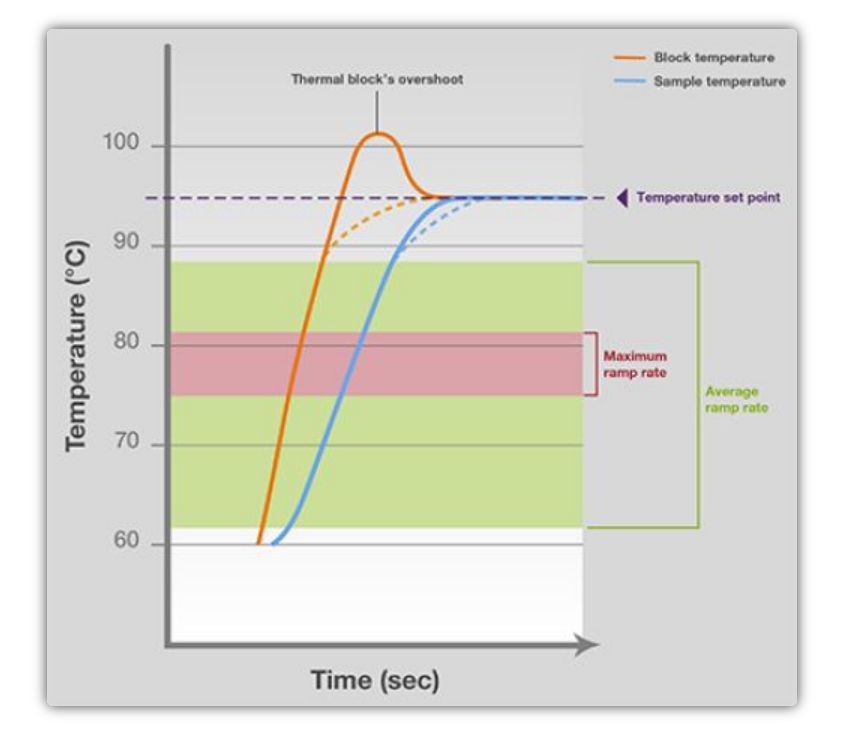

The rate of heating and cooling of the PCR machine means that the temperature changes between PCR steps that occur over a certain period of time. Since it takes a certain amount of time for the heat to transfer from the module to the sample, the actual heating and cooling rate of the sample will be slower. Therefore, the definition of temperature change speed needs to be distinguished and understood.

The maximum or peak module ramp rate represents the fastest temperature change that the module can achieve over a very small period of time during the ramp.

The average block ramp rate represents the rate of temperature change over a longer period of time and will provide a more representative measure of PCR machine speed.

The maximum sample heating and cooling rate and the average sample heating and cooling rate reflect the actual temperature obtained by the sample. The rate of sample heating and cooling will provide a more accurate comparison of the performance of the PCR machine and its potential impact on PCR results.

When performing a cycler replacement, it is recommended to use an instrument with a ramp rate program that simulates the previous mode for easier replacement and minimal impact on PCR repeatability.

The thermal cycler should be designed to time steps only after the sample reaches the set temperature. In this way, the time that the sample is maintained at the set temperature will be more accurately maintained with the corresponding cycle conditions required in the operating procedure.

Thermal cyclers often use complex mathematical algorithms to ensure that samples can quickly reach a set temperature according to a preset program. Based on the volume of the reaction system and the thickness of the PCR plastics used, the algorithm can predict the temperature of the sample and the time it will take to reach the set temperature. Relying on these algorithms, during the heating or cooling process of the thermal cycler, the block temperature will usually exceed the set value through a process called thermal block overshoot or undershoot. Such a setup ensures that the sample reaches the set temperature as quickly as possible without overshooting or undershooting itself.

Experimental throughput

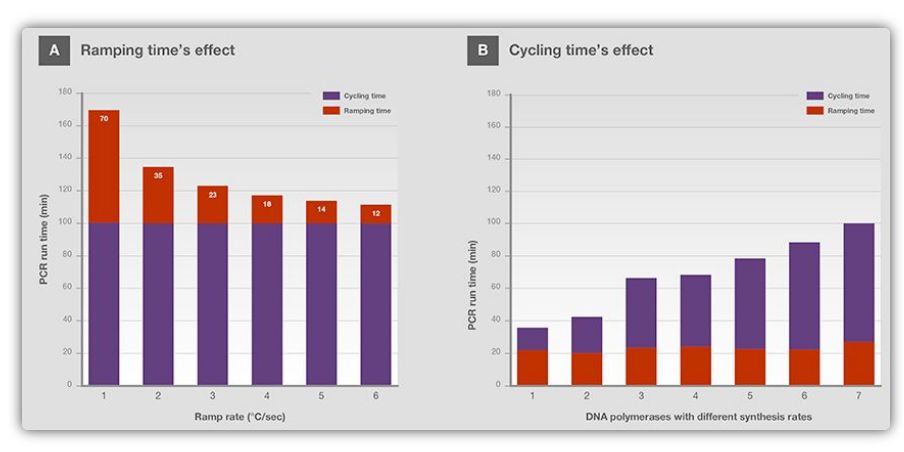

Factors that can increase the throughput of a thermal cycler include ramp rates, thermal block configurations, and integration of automation platforms.

The heating and cooling rate of the thermal cycler represents the speed at which it reaches the set temperature. The faster the temperature rise and fall, the faster the PCR will run, which means that more experiments can be completed in a given period of time. In addition, experiments can be accelerated by using faster DNA polymerases.

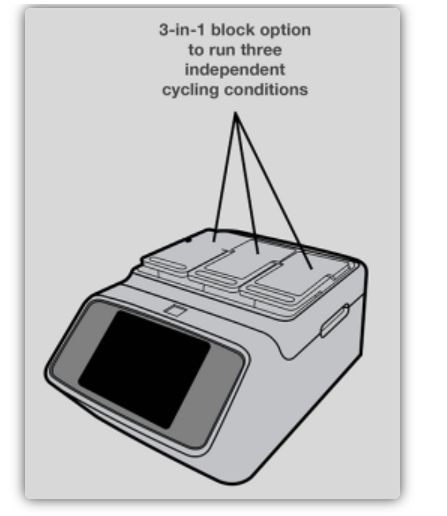

The design of the thermal cycler module is also crucial for PCR experiments. For example, replaceable modules allow flexibility in the number of samples per run. In addition, heating modules with individually controllable modules are ideal for running different PCR programs simultaneously on one thermal cycler.

For automated high-throughput PCR, the software that controls the pipetting handling system should be programmable and compatible. Automated systems are ideal for performing high-throughput PCR reactions because they can be run continuously with little human intervention, thereby minimizing the time required for manual experimental setup and increasing the number of reactions in a given time period .

Reliability, Durability and Quality Assurance of Thermal Cyclers

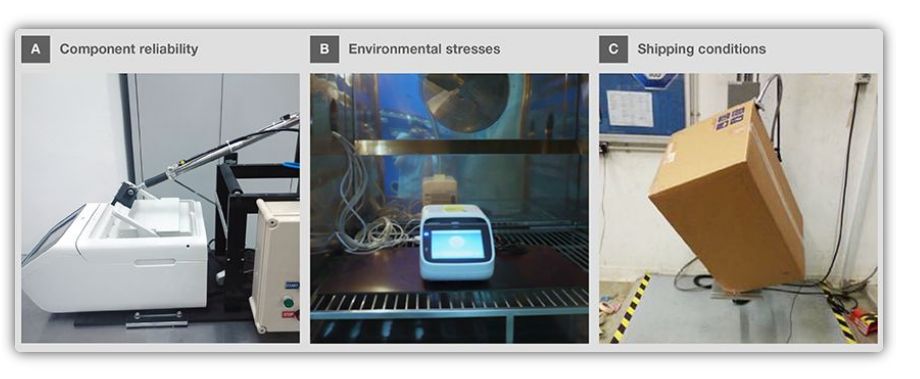

In addition to performance and throughput capabilities, the PCR machine should also be able to withstand certain repeated use, environmental stress, and shipping conditions. Some manufacturers may report on how the instrument performs reliability and durability tests. The corresponding PCR instrument detection includes:

Reliability: Mechanical rigs are used to perform repeated tests on frequently used instrument components such as thermal lids, control panels/touchscreens, and temperature cycling modules.

Ambient pressure: Environmental chambers can be used to simulate different conditions of routine experiments, such as temperature, humidity.

Shipping Testing: Intense shock and vibration testing can be performed according to International Safety Shipping Association standards to ensure the instrument can arrive in undamaged operating conditions.

Warranty and service for maintaining the PCR machine

Despite rigorous reliability and durability testing, thermal cyclers inevitably have technical issues over the life of the instrument. For peace of mind, the manufacturer’s warranty, service, and maintenance should be considered when purchasing an instrument.

The flexibility of services such as on-site/return-to-factory maintenance, remote monitoring services, and replacement instruments in the maintenance process, etc., to reduce the impact on work efficiency.

The length of the warranty period, the turnaround time of the service, the accessibility of technical support, and the skills of professional support personnel.

Feasibility of instrument installation, operation, cooperation, and verification to meet laboratory and related regulatory requirements. Maintenance services such as temperature verification, testing, and calibration are available to ensure that the instrument performs properly with the corresponding parameters.

Related Products:

Post time: Oct-18-2022